How to maintain outboard motors on boats?

- Home

- Blog

- Outboard motors

- How to maintain an outboard motors on boats

Outboard motors are a popular choice for powering boats, and with proper maintenance, they can provide many years of reliable service. However, like any mechanical device, outboard motors require regular care and attention to ensure that they run smoothly and efficiently.

Outboard motors are a popular choice for powering boats, and with proper maintenance, they can provide many years of reliable service. However, like any mechanical device, outboard motors require regular care and attention to ensure that they run smoothly and efficiently.

One of the most important maintenance tasks for an outboard motor is checking and changing the oil. The oil in an outboard motor needs to be changed at regular intervals to remove contaminants and keep the motor lubricated. The oil should be changed every 100 hours of operation or once a year, whichever comes first. When changing the oil, it is important to use the correct type of oil recommended by the manufacturer, and to dispose of the used oil properly.

Another important maintenance task is cleaning and inspecting the air filter. The air filter ensures that the motor is getting enough air for proper combustion, so it is important to keep it clean and in good condition. The air filter should be inspected every 100 hours or once a year, and cleaned or replaced as necessary.

Flushing the motor with fresh water is also important, especially if the boat is operated in saltwater. Saltwater can cause corrosion and buildup in the motor, so it is important to flush it out after every use. This can be done by attaching a flushing device to the motor's water intake and running the motor for a few minutes.

Checking and adjusting the spark plugs is another important maintenance task. Spark plugs are responsible for igniting the fuel in the motor, so it's essential to keep them in good condition. The spark plugs should be checked every 100 hours or once a year, and replaced if necessary.

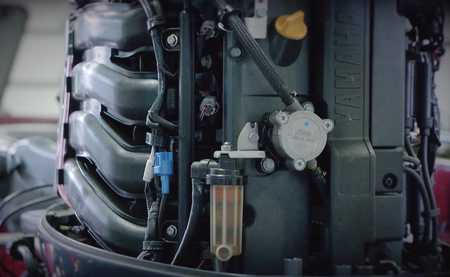

The fuel system is another important part of an outboard motor that needs regular maintenance. The fuel filter should be checked and replaced if necessary, and the fuel lines should be inspected for leaks or cracks. Keeping the fuel system clean and in good condition will help the motor run smoothly and efficiently.

The water pump impeller is another critical component that needs regular attention. The water pump impeller pushes water through the motor to keep it cool, so it's essential to keep it in good condition. The water pump impeller should be inspected every year and replaced if necessary.

Finally, it's important to service the lower unit. The lower unit contains the gears and oil that lubricate the drive shaft and propeller. It should be serviced every 100 hours or once a year, whichever comes first. This includes checking and replacing the gear oil and inspecting the gears for wear or damage.

It is also important to refer to the manufacturer's maintenance schedule and owner's manual for specific recommendations and instructions. Additionally, it is always best to have an experienced and trained technician to perform the maintenance, especially for the complex tasks such as lower unit servicing.

However, it's also important to be aware of the signs of a malfunctioning outboard motor. Some common signs include poor performance, difficulty starting, strange noises, and warning lights or alarms. If any of these issues arise, it's best to have the motor inspected by a professional as soon as possible to prevent further damage and costly repairs.

Proper maintenance not only ensures that the motor runs efficiently but also prolongs its lifespan. However, it is also important to be aware of the signs of a malfunctioning outboard motor, such as poor performance, difficulty starting, strange noises, and warning lights or alarms. If any of these issues arise, it is best to have the motor inspected by a professional as soon as possible to prevent further damage and costly repairs.